Oil milling companies depend on high tech technologies for oil processing. This ensures the purity of the refined oil and cost efficient ways to do it. Researchers and inventors work day and night to invent new methods and machines to provide cost efficient and more productive ways for the industry. Pressure leaf filters have created a popularity of its own among the oil milling companies all around the world. It uses pressure to filter oil from impure mixture of different particles. Depending on the design of its vessel, there are two types of pressure leaf filters available. One is called vertical pressure leaf filter and the other one is called horizontal pressure leaf filter. Oil milling companies use both of these filters according to their needs. More details about horizontal pressure leaf filter are given below.

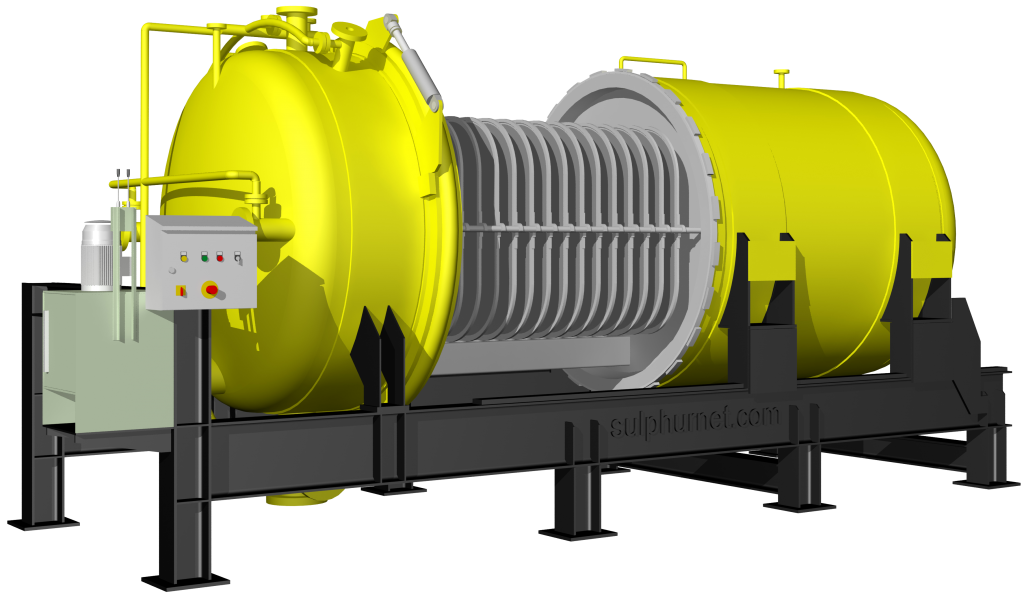

Horizontal pressure leaf filters have earned their popularity among the oil milling companies because of their eco friendly equipments and user friendly mechanism. Manufacturers make these filters with highly standardized and well designed features. The horizontal tank is built with an accessible cover top that enables the operators to seal the framing joint with the tank. The filter leaves are placed in horizontal manner in the vessel. The filters extract the liquid from all the impure matters in the mixture of different materials. Oil milling companies use this filter to separate the filtered cakes from the filtrate ones. Horizontal pressure filters are mostly used in case of cakes which are sticky and difficult to remove. It is also used for filtering highly flammable and toxic materials. The mechanism of horizontal pressure leaf filter is rather simple than other filters available in the market. It has a removable shaft that enables the operator to discharge the filtered cakes manually. The discharge can also be done by an automated vibrator. As the shaft is accessible during the discharge, it is easy to monitor if the discharging process is going smoothly. The horizontal pressure filters also have some vertically placed vessels that support the stack of plates situated inside the horizontal tank at the bottom. Horizontal filters can have two types of bottom designs for outlets. One is conical shaped bottom that discharges the sludge by gravity. The other one is dish shaped bottom that stacks the cakes and then send it to the discharging outlet. It has safe outlet system that ensures no spillage of impure materials and keeps the discharged materials sealed inside the machine.

The horizontal pressure leaf filters provide high productivity with high rate of clarity. It is highly recommended for oil milling companies that has large amount of liquid to process. It can be built in more units than the vertical pressure leaf filters. Operators with little training can operate this filter because of its simple interface. It is available in various sizes and capacities for meeting different types of customer demands.